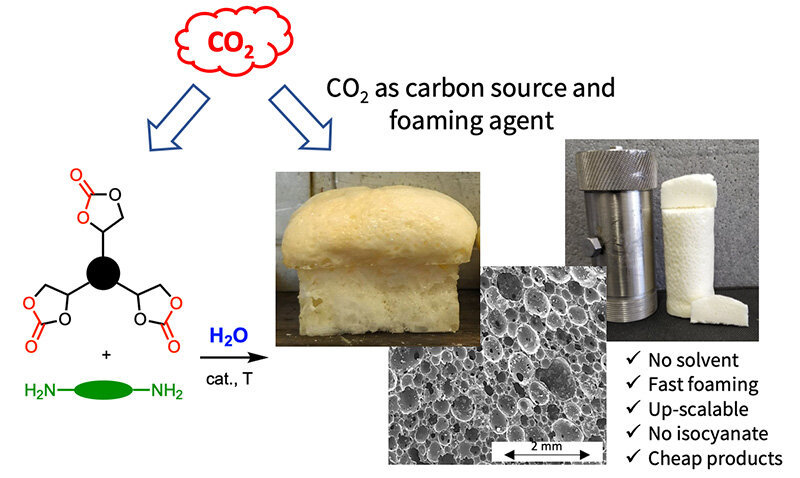

Water and carbon dioxide to produce isocyanate-free polyurethane foams.

Credit: CERM / University of Liège

A team of researchers from the Center for Education and Research on Macromolecules (CERM) at the University of Liège (Belgium) has developed an innovative process that rethinks the manufacturing of polyurethane (PU) foams without the use of isocyanates—highly toxic agents—while being recyclable. This study is published in the journal Angewandte Chemie International Edition.

Polyurethane (PU) foams are indispensable products in our daily-life, and are available as rigid and flexible materials. For decades, rigid PU foams have played a major role in energy savings when used as the most efficient insulating panels in the construction sector (e.g., floor, wall and roof insulation in buildings) or in household items such as refrigerators (walls and doors). Flexible PU foams are used as comfort materials, e.g., mattresses, sofas, armchairs, car seats, etc., but are also used for sound insulation and shock protection.

Although inexpensive, these materials are prepared from toxic compounds and are difficult to recycle. "PU foams are prepared from isocyanates, which are highly reactive and toxic chemical substances," explains Christophe Detrembleur, FNRS Research Director at the Center for Education and Research on Macromolecules (CERM) within the CESAM research unit at the University of Liège.

Replacing this old chemistry with a more environmentally and health-friendly one, while valorizing an emblematic waste (CO2) as a raw material, has become a priority for the production of more ecological and recyclable cellular materials.

Also facing regulatory changes restricting the use of isocyanates, the manufacture of PU foams has to change. Researchers at the University of Liège have developed a new process, potentially compatible with existing industrial foaming infrastructures, to prepare isocyanate-free and recyclable polyurethane (NIPU) foams using water to generate the blowing agent.

"We have succeeded," says Maxime Bourguignon, a researcher in the lab and first author of the article, "in mimicking the foaming technology of conventional polyurethanes by replacing the toxic isocyanates with easily accessible cyclic carbonate compounds. Our technology uses water and a catalyst to convert part of the cyclic carbonates into a gas (CO2 ) that blows the matrix, while the other part simultaneously reacts with amines to cure the foam. The result is a solid material with a low density and regular pores. Our cyclic carbonates are easily obtained by chemical transformation of CO2 and thus fulfill a dual role, generating the blowing agent and forming the polymer matrix, the polyurethane."

The simplicity, modularity and ease of implementation of the technology combined with the use of low-cost and most widely available starting products is a new impetus for the next generation of more sustainable PU foams. Production is expected to ultimately respond to legislative changes imposed to the chemistry sector, but also to societal needs and sustainability requirements of crucial importance for many sectors.

Source:Phys.org (www.phys.org)

Key Words:

#Polyurethane, #Foams, #Sustainable, #Recycle, #Isocyanate-free Foam, #PU, #Materials, #CO2, #NIPU