Why do we need to address EMC?

High-capacity and high-speed data transmission systems, technological infrastructure supporting today’s society:

EMC measures for controlling noise is now essential technology.

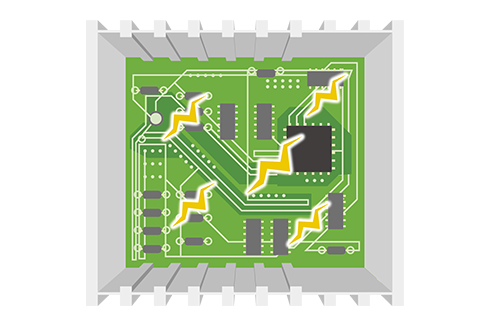

Efficient EMC measures need to be taken to prevent functional errors due to the noise emitted from the circuit board and cables, and reflected by the metal casing.

The 5th Generation (5G) Mobile Communication System and Internet of Things (IoT), which were called “next-generation technology” several years ago, are now being constructed as new social infrastructure.

However, with the progress and spread of the above transmission technology and related electronic devices, noise problems have arisen. Noise is unnecessary electric energy occurring unintentionally, which is unwanted.

To mitigate or eliminate noise, electromagnetic compatibility (EMC) measures are taken. With the performance enhancement and downsizing (integration) of electronic devices, it is said that higher degrees of EMC measures are required.

Sekisui EMC proposal

Having effects on items concealed from view:

The EMC products from the Sekisui Group are widely used around the world.

In its long history, Sekisui Group has been defined by its core technology based on processing plastics, and marketed many products including foam, tapes, and formed plastic products.

As a piece of leading-edge technology, we have been developing EMC products using our core technological assets. Our EMC products have already been applied in smartphones and on-board devices without being noticed but constantly serve their purpose.

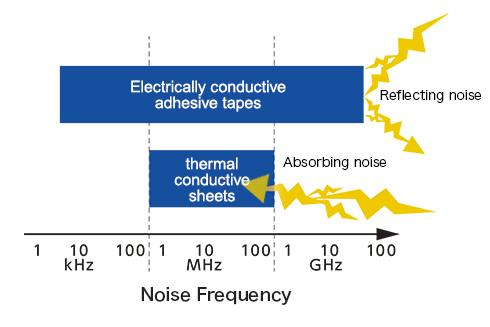

Our products include 7800-Series electrically conductive adhesive tapes, thin tapes with electrical conductivity, and Heat Dissipating Electromagnetic Wave Absorbing Sheets, thermal conductive sheets that absorb electromagnetic waves, which have been increasing their presence as generally-used EMC design materials.

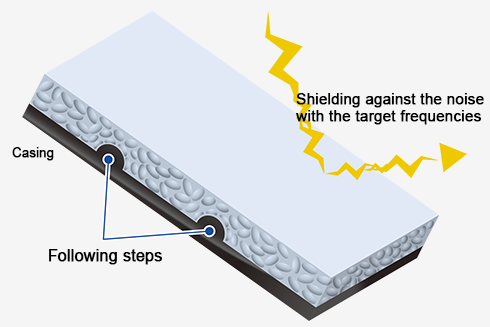

Features of EMC customized foam

Shielding against noise with the target frequencies and additional features:

Flexible foam promotes the technological innovation of automobiles and antennas.

Flexibility, heat insulation, shock absorption (cushioning), etc.

The importance of EMC has been ever increasing. Inheriting the policy of the Sekisui Group, constantly seeking leading-edge technology, Sekisui foam is leading this new field of technology.

Exploiting the characteristics of Softlon, our conventional Sekisui foam has been used in various markets as cushioning, sealing, heat-insulating, and low-dielectric materials.

And now, while preserving the advantages of foam, we are developing the leading-edge technology for providing shielding against electromagnetic waves with special processing.

Once this technology is established, the new foam will be able to offer additional properties including shock absorption and sealing (gasket), as well as shielding against electromagnetic waves with the frequencies selectable.

With the intention of expanding applications to various fields including on-board devices where the transition to MaaS has started to gain momentum, and industry devices that are facing the spread of IoT, our development efforts are beginning to bear fruit.

Source:SEKISUI

Key Words:

#Foam, #Interfoam, #Control Technology, #EMC, #Flexible Foam, #Customized Foam