Ms. Katelyn Xue

Sr. Manager of Data Center,HJT EXPO

| Phone | +86 21 6323 2733 |

|---|---|

| Fax | +86 21 6323 2733 |

| katelyn.xue@hjtexpo.com | |

| Address | 5th floor, World Trade Tower, 500 Guangdong Road, Huangpu District, Shanghai |

Recently, there are so many news about new energy vehicles:

- Tesla announced that it will adopt more advanced casting and cold forging technologies in its new factory to achieve a vehicle structure for more lightweight.

- Toyota announced that it will adopt more lightweight magnesium alloy materials in its new hybrid vehicles to achieve higher energy efficiency and longer battery life.

- BMW announced that it will adopt more advanced carbon fiber materials in its new electric vehicles to achieve a more lightweight vehicle body structure.

It is evident that major global automakers are accelerating their research and development of new lightweight materials and manufacturing processes.

With the increasingly prominent issues of crises in environmental protection and energy, lightweighting in new energy vehicles has become a pivotal trend for future development.

"Made in China 2025" identifies lightweight materials as a focus for industrialization, with the goal of achieving a 30% reduction in vehicle weight by 2025.

Compared to other materials, melamine foam is more widely used in the field of electric vehicles due to its outstanding properties such as lightweighting, sound-absorbing, and insulation.

Multiple Functions of Melamine Foam

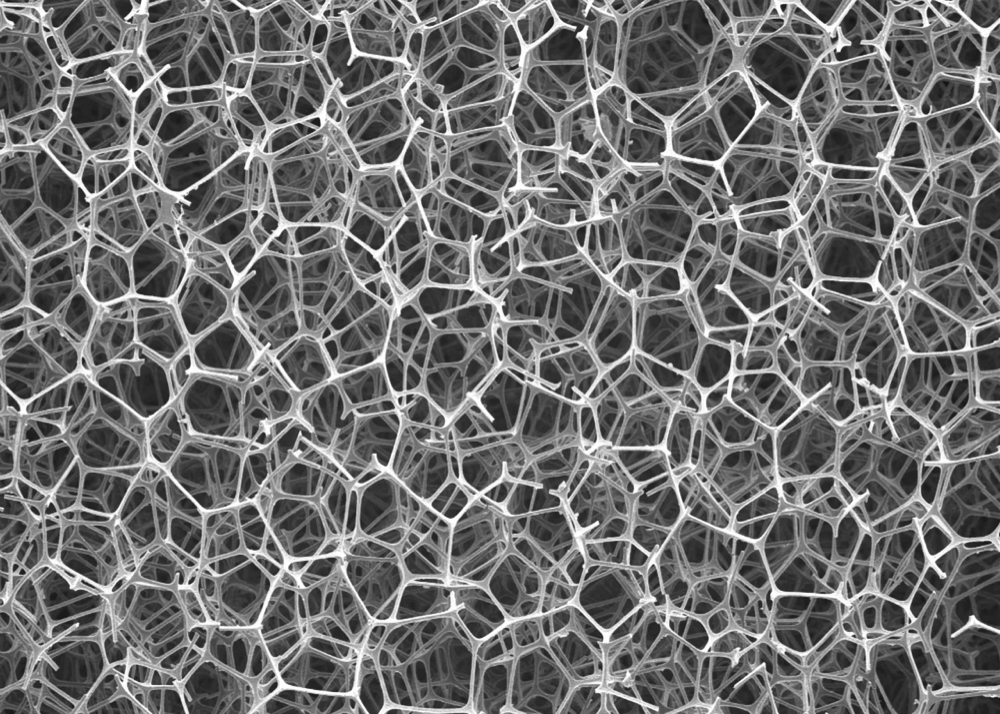

Melamine foam plastic is a type of foam with a three-dimensional reticular structure that resembles animal bones and spider silk when observed under a microscope. This structure gives melamine foam excellent support and shock-absorbing properties.

Image:Internet

In addition, melamine foam has another prominent feature: the porosity is over 99%.

Therefore, due to the unique high porosity and spiderweb-shaped structure, melamine foam has superior thermal stability and cold resistance compared to traditional foam materials such as polyethylene, polypropylene, and polyurethane. It also has excellent sound absorption, noise reduction, and insulation properties.

Melamine foam is considered a promising new environmentally friendly material in the 21st century.

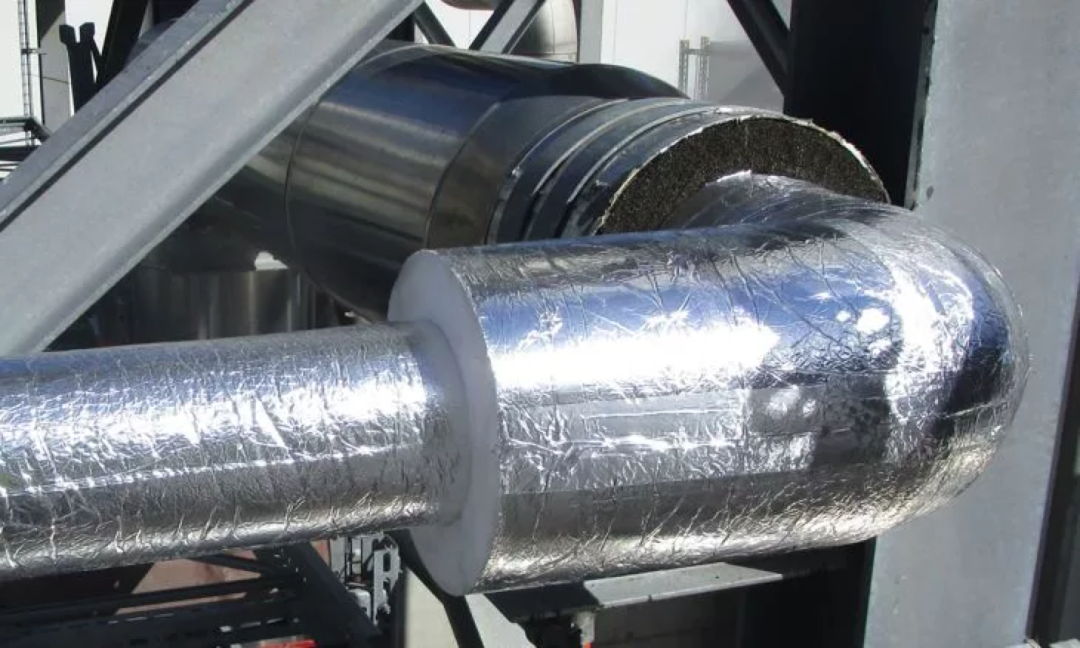

Image:FoamTech

With the density of only 7-9kg/m3, melamine foam is one of the lightest foam materials in the current market.

Some of its strengths are as follows:

Image:A new grade of melamine resin foam recently developed by BASF.

As a low-temperature flexible foam, it is suitable for low-temperature applications and energy-saving insulation. Its unique properties make it an ideal material for insulating LOX and LNG pipelines, storage tanks, and gas processing machinery.

High Sound Absorption Performance

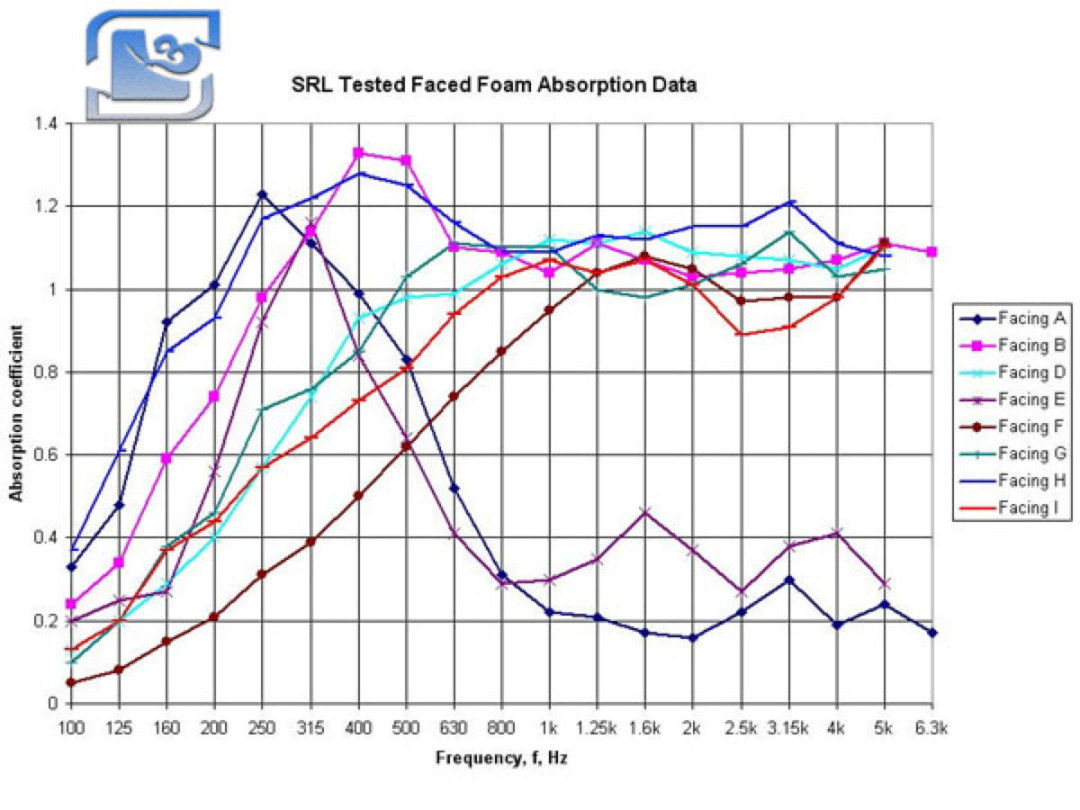

The high porosity of melamine foam (up to 95%) allows sound waves to enter the deep layer of the foam more conveniently and effectively, which are consumed and absorbed after transforming into grid vibrations. Besides, this structure can also effectively eliminate reflected waves.

The absorption performance is particularly outstanding for mid-to-high frequency noises.

Image:Noise absorption test data of ENDA automotive melamine foam.

High Flame Retardancy

With three cyano groups in each molecule, melamine foam has a high nitrogen content of up to 70%. At high temperatures, it releases a large amount of water and carbon dioxide, forming a protective layer of nitride that effectively inhibits flame spread.

Even without adding flame retardants, it can meet the German DIN4102 B1-level low flammability material standard and the American Insurance Association UL 94-V-0 high flame retardancy material standard.

It has also been certified by the EU BS6853, NFF16-101, and DIN5510 fire protection standards, while complying with China's GBIT8624-2006 B1-level flame retardancy standard.

Image:CLEAN WORLD, non-flammable melamine foam for car interiors.

Thermal Insulation

The fully opened three-dimensional reticular structure system with a length-to-diameter(L/D) ratio between 10-20 enables efficient thermal convection to be blocked. Together with its low thermal stability, the special precise three-dimensional reticular structure exhibits excellent insulation and heat preservation performance.

High Temperature Resistance

Compared with traditional polyethylene, polypropylene, and polyurethane foam materials with low cross-linking degree, melamine foam can work stably in the temperature range of -180°C to 200°C for a long time, and can withstand high temperatures up to 240°C for a short time.

Lightweight

The product bulk density is between 4-12 kg/m³, making it one of the super-light foam plastics in the world.

Stability

The stability of melamine foam allows it to operate in a temperature range of -180℃ to +240℃ for a long time and withstand a maximum temperature of +240℃ and a minimum temperature of -180℃.

Application in New Energy Vehicles

The main strength of melamine is that it significantly improves the lightweighting, NVH (noise, vibration, and harshness), and safety of new energy vehicles.

Advantage 1

Lightweight, reducing energy consumption and emissions.

Research has shown that reducing the weight of electric vehicles by 10kg can increase the driving range by 2.5km, while increasing the weight of the vehicle by 10% can reduce the driving range on a single charge by 8%.

Lightweighting reduces the overall weight of the vehicle, thereby reducing energy consumption and improving the driving range on a single charge.

Triamine foam is known as one of the world's lightest foams.

With its 99% porosity and three-dimensional reticular structure system, it is more like the hollow bones of birds, and its density is of only 4-12kg/m³. In addition to reducing its own weight by 90%, it also greatly reduces the weight of the vehicle, meeting the growing demand for weight and emission reduction.

Advantage 2

Excellent insulation performance

When new energy vehicles are driven at high speeds or under high power output, the electric motor generates a large amount of heat, typically ranging between 80°C to 120°C.

Therefore, good heat dissipation and insulation design is required for these critical components.

Image:Internet

99% porosity of melamine foam allows air to fill the interior of the material and undergo sufficient heat exchange, thereby minimizing heat accumulation.

Its thermal conductivity ranges from 0.022 to 0.036 W/(m·K), which means that it has lower thermal conductivity, effectively blocking heat transfer.

Advantage 3

High sound absorption performance

The noise in new energy vehicles mainly comes from motor vibration, tire friction with the ground, air whistling, and vehicle body resonance.

Currently, the major noise reduction measure taken by automakers is using sound-absorbing materials to separate and absorb noise.

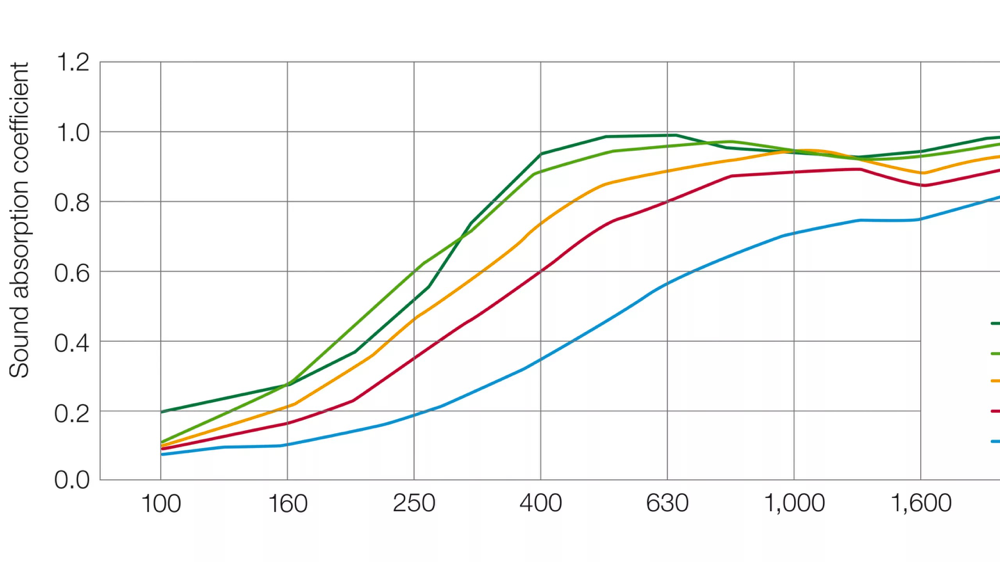

Image:WAVE acoustic module manufactured by BASF.

Image:WAVE acoustic module manufactured by BASF.

Melamine foam can absorb sound waves and convert them into weak heat energy, reducing sound propagation and lowering in-car noise. Other sound waves will be reflected or refracted by the foam, forming a sound barrier that can also block sound propagation.

Image:Sound absorption data model of the melamine foam material — Basotect by BASF (reverberation chamber).

Advantage

High Fire Resistance

Components such as the battery pack and electronic control system of electric vehicles generate high temperatures, thus requiring materials with excellent flame retardancy and fire resistance.

The flammability rating of melamine foam reaches B1, which means it is a non-flammable material. When exposed to flames, the material will not melt or produce burning droplets, and will only carbonizes and generates a small amount of smoke.

Additionally, it can effectively suppress the generation of smoke and harmful gases, exhibiting excellent fire resistance.

Advantage 5

High Shock Absorption Performance

The unique three-dimensional reticular structure of melamine foam is similar to the honeycomb structure of beehives.

This structure allows it to disperse vibration waves through its reticular structure, achieving excellent shock absorption. Melamine foam provides strong support and good rebound resilience for new energy vehicles.

Advantage

Good Environmental Friendliness

Since the manufacturing of melamine foam does not involve harmful substances such as fluorocarbons, it has a relatively low environmental impact. Additionally, it is highly recyclable, making it an environmentally-friendly choice that can reduce resource waste and pollution.

Melamine Foam in other Industries

Apart from the automotive industry, melamine foam is also widely applied in other fields.

Anhui Hefei Grand Theater

The Anhui Hefei Grand Theater, with a total investment of approximately 650 million yuan and covering an area of 57,000 square meters, also adopted melamine foam in its interior design.

Image:Internet

BASF foam is wrapped around the top of the static pressure box that supports the seat bases in the theater, reducing sound reflection on the surface and echo caused by multiple reflections due to its good sound absorption performance.

At the same time, it provides excellent insulation performance, ensuring that the air flowing through the air ducts under the theater seats remains cool.

Soilless Cultivation Substrate

1 gram of regular polyurethane foam can absorb 30 grams of water, while 1 gram of melamine foam can absorb 300 grams of water, which is 10 times the water absorption capacity of polyurethane foam.

Melamine foam can also be used as a substrate for soilless cultivation. In addition to its strong water retention ability, it also has anti-aging and strong antibacterial properties, stable performance, and can be soaked in nutrient solution for a long time without deformation or aging.

Image:Yadina

Zhejiang Yadina's melamine foam has a porous structure on the surface and a large internal porosity compared to ordinary foams, making it a promising material in the field of soilless cultivation.

Transportation under Harsh conditions

On the desert of Medina and Mecca in Saudi Arabia, where the temperature between day and night differentiates greatly, to ensure the running of a high-speed train causes huge challenges for manufacturers during the production and material selection.

Image:BASF

The BASF melamine foam resin, with its noise absorption, fire resistance and thermal insulation properties, can be applied to cover the interior walls and ceilings of the train compartments, offering passengers optimal acoustic experience and balanced temperature inside the train.

Image:BASF

BASF's New Technology

BASF recently developed a flexible open-cell foam made from melamine resin.

One typical feature is its complex spatial grid structure formed by thin ribs, which allows it to be easily bent and shaped while providing excellent sound absorption performance, lightweight property, high temperature resistance, and low flammability.

Image:BASF

This material can significantly improve the acoustic performance of cafeteria, reception areas, meeting rooms, cabins, etc., and can also be applied to thermal insulation and air conditioning technology.

Overall, as a new type of material for new energy vehicles, melamine foam is widely used in general insulation, battery insulation, sound insulation and noise reduction, etc., with its unique advantages that other materials do not have.

With technological development and innovation, it is expected that melamine foam will be adopted more widely in the automotive field in the future, such as autonomous driving, intelligent transportation, etc. Melamine foam will embrace better development prospects.

Global Outstanding Exhibitors in Melamine Foam

Basic information about some companies with high reputation in the field of foam materials are collected as follows:

ZHEJIANG YADINA NEW MATERIAL TECHNOLOGY CO.,LTD

As a Chinese enterprise established in 2002, it is a comprehensive company that integrates independent R&D, professional production, and sales of modified melamine formaldehyde resin and melamine foam plastics.

BASF China

https://www.basf.com/cn/zh.html

BASF China is a leading chemical company in the world, with products including polyurethane, polystyrene and other foaming materials applied in the fields of construction, automotive, electronics, etc.

Zhengzhou FoamTech Nano Materials Co.,Ltd.

It is a high-tech enterprise specializing in the research, development, production, and sales of environmentally friendly nanometer-grade polyimide foam. It has more than 100 patents for invention and utility model to protect the production technology of melamine foam.

Disclaimer: The content is compiled based on information from the internet, with the purpose of sharing and conveying more information, and does not imply endorsement of its views or confirmation of its authenticity, nor does it constitute other advice. We only provide a communication platform and do not take responsibility for the copyright. If there is any infringement, please contact us for timely modification or deletion.

Phone: 010-5867 8210

Email: marketing@interfoam.cn

Key Words:#New Energy Vehicles, #Tesla, #Carbon Fiber Materials, #Melamine Foam Plastic, #Sound Absorption, #Insulation, #Noise Reduction, #BASF, #Flame Retardancy

Sr. Manager of Data Center,HJT EXPO

| Phone | +86 21 6323 2733 |

|---|---|

| Fax | +86 21 6323 2733 |

| katelyn.xue@hjtexpo.com | |

| Address | 5th floor, World Trade Tower, 500 Guangdong Road, Huangpu District, Shanghai |

Please browse vertically for better experience.